WHAT WE CAN DO FOR YOU

Our Services

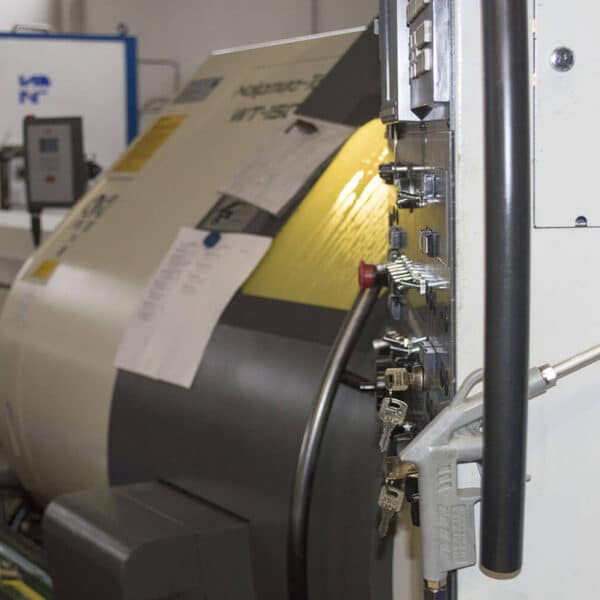

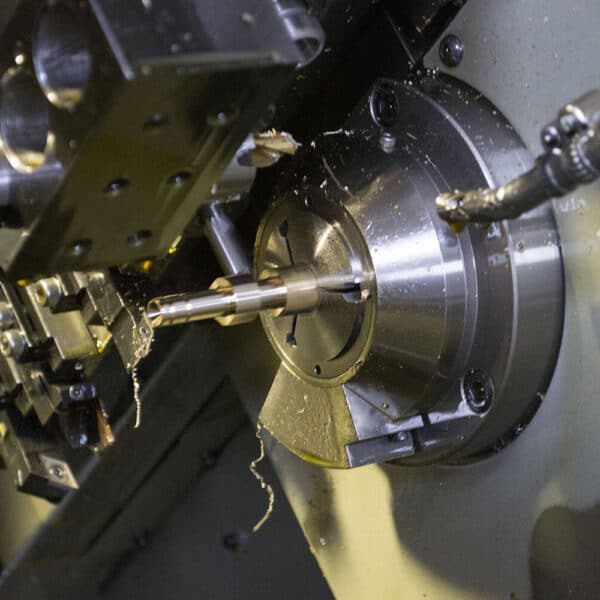

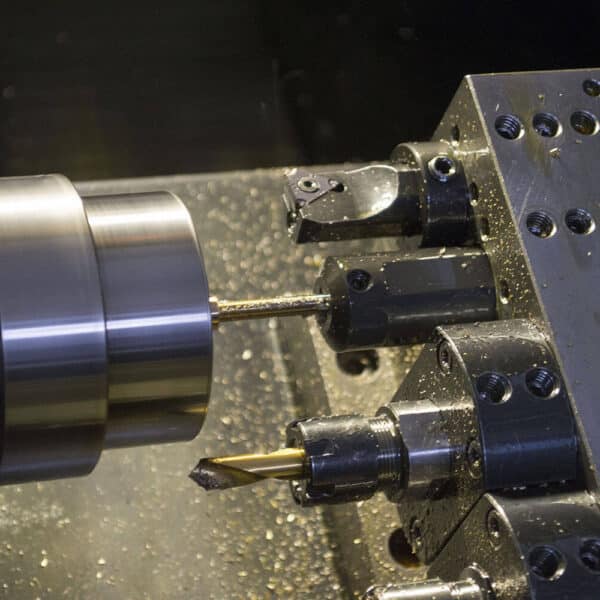

Tecnometal, thanks to its machinery park and highly qualified staff, can ensure execution of any part to design with continuous bar processing from a minimum of 5mm to a maximum of 65 mm. We can provide surface treatments such as galvanising, tempering, burnishing, nickel-plating and anodization, carried out by highly qualified suppliers.

Tecnometal guarantees orders using software that controls the machinery load, allowing us to provide clients with precise deliveries.

Burnishing

It improves resistance to corrosion and does not create thickness.

This treatment colours metal black and presents an even, polished and coated appearance, to improve its resistance to corrosion. However, the geometric characteristics do not change and thickness is not created as material is penetrated.

Nickel-Plating

It changes the surface characteristics of materials.

Nickel-plating is distinguished in two processing methods: electrolytic nickel-plating and chemical nickel-plating.

The scope of the treatment is to modify the surface characteristics of the processed materials.

Chrome-Plating

It changes the surface characteristics of materials.

Nickel-plating is distinguished in two processing methods: electrolytic nickel-plating and chemical nickel-plating. The scope of the treatment is to modify the surface characteristics of the processed materials.

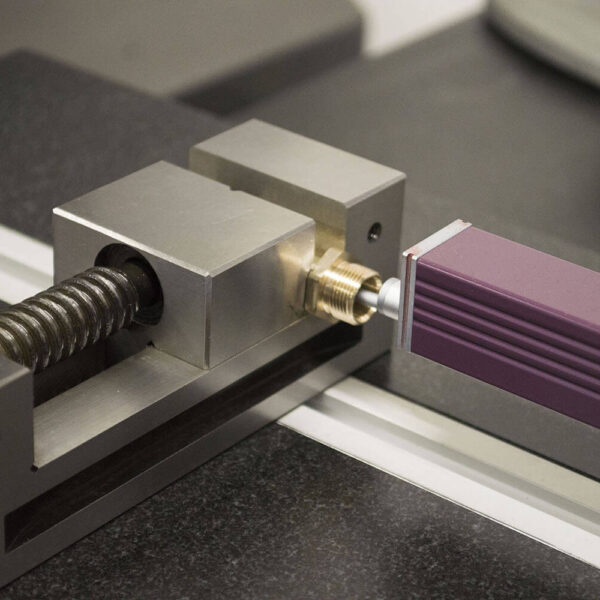

Anodization

Electrochemical process that fixes an oxide layer on the metal surface.

Anodic oxidation is an electro-chemical process that creates a layer of aluminium oxide on the surfaces.

The layer is variable and is divided in a thin treatment with a layer of 5/20 micron and a semi-hard layer of 20/30 micron. A considerable variety of colours are obtained.

Galvanising

A zinc coating is applied that protects against galvanic corrosion.

Widely used, galvanising is a process carried out by submerging metals in an electrolyte bath containing zinc salts.

A current passage is created between the part and the solution that allows zinc to be evenly deposited on the surface of the part.

Surface Treatments

Important on finished parts to make everything more resistant to corrosion.

We also provide complete surface treatment products that make the parts more resistant to corrosion. Each client requires treatment based on their needs. For this reason, we avail of structures that guarantee them with their systems.

The considerable experience gained through years of work and constant innovation, combined with precision mechanical processing in various types of materials such as titanium, alloy steel, stainless steel, tempered materials, aluminium, brass, plastic, allow the company to work in various industrial sectors.

Our main objective is to provide a broad, complete and efficient service to the client in mechanical precision; continuous and new experience allows us to promptly meet various needs for all treatments.